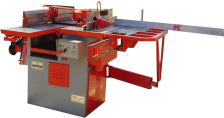

K5 320

Тechnical specification of K5 320

| Technical data | Dim. | Value |

|---|---|---|

| Planer | ||

| Work table size | mm | 1560x320 |

| Maximal depth of cut | mm | 4 |

| Diameter of the cutter block | mm | 86 |

| Cutter block speed | min-1 | 5200 |

| Number of cutters | pcs | 3 |

| Thicknesser | ||

| Work table size | mm | 550x320 |

| Maximal depth of cut | mm | 3 |

| Feeding speed | m/min | 8 |

| Thickness of work detail max. | mm | 180 |

| Number of cutters | pcs | 3 |

| Cutter block speed | min-1 | 5200 |

| Circular saw | ||

| Work table size | mm | 850x450 |

| Saw blade diameter | mm | 300 |

| Spindle diameter | mm | 30 |

| Maximal height of cut | mm | 85 |

| Spindle speed | min-1 | 3700 |

| Spindle moulder | ||

| Work table size | mm | 850x450 |

| Spindle diameter | mm | 30 (50 - optional) |

| Spindle vertical movement | mm | 130 |

| Tool max diameter | mm | 190 |

| Spindle speed - 2 speed motor | min-1 | 6000 (3000/6000) |

| Mortiser | ||

| Drill maximal size | mm | 16 |

| Work table size | mm | 400x250 (500 - optional) |

| Longitudinal stroke | mm | 100 (150 - optional) |

| Traverse stroke | mm | 100 (150 - optional) |

| Vertical stroke | mm | 100 (150 - optional) |

| Drill speed | min-1 | 5200 |

| Motor | ||

| Planer motor power | KW | 2.2 |

| Thicknesser motor power | KW | 2.2 |

| Circular saw motor power | KW | 2.2 |

| Spindle moulder motor power - 2 speeds | KW | 2.2 |

| Size | ||

| Length | mm | 1650 |

| Width | mm | 1140 |

| Height | mm | 1100 |

| Weight | ||

| Net weight | kg | 450 |

Standard equipment

Machines are equipped with three induction motors to drive aggregates. Standard machines are three-phased 220/380 V, 50 H, 2800 cycles/min. At client’s request, the machines are offered with various tensions, powers, frequencies and cycles, incl. continuously variable cycle regulation /optional/. Every aggregate is independently controlled. Technical safety requirements prevent simultaneous work of two aggregates! Electric installation renders easy and handy aggregate starting and stopping /incl. in case of emergencies/, overburdening protection of motors and dust protection /IP-54/.